Manufacturing Process Polyolefin Shrink Film

Step 1: Raw Materials ~ Polyolefin Shrink Film Manufacturing

Firstly, the raw materials, typically polyethylene or polypropylene resins, are mixed with additives such as slip agents, anti-block agents, and UV stabilizers. These additives enhance the film’s properties and processing characteristics.

Step 2: Film Coextrusion ~ Manufacturing Polyolefin Film

Next, the resin mixture is melted in an extruder and formed into a flat sheet through a die. The sheet is then cooled and solidified, forming a thin film.

Step 3: Biaxial Orientation ~ Manufacturing Process

After solidification, the film is stretched biaxially using a tenter frame or a blown film process. Biaxial stretching improves the film’s tensile strength, clarity, and shrinkability.

Step 4: Jumbo Rolls ~ Polyolefin POF Shrink Film

Once stretched, the film undergoes a heat-setting process to stabilize its dimensions. This step ensures that the film retains its shape and size when subjected to heat during the shrink process.

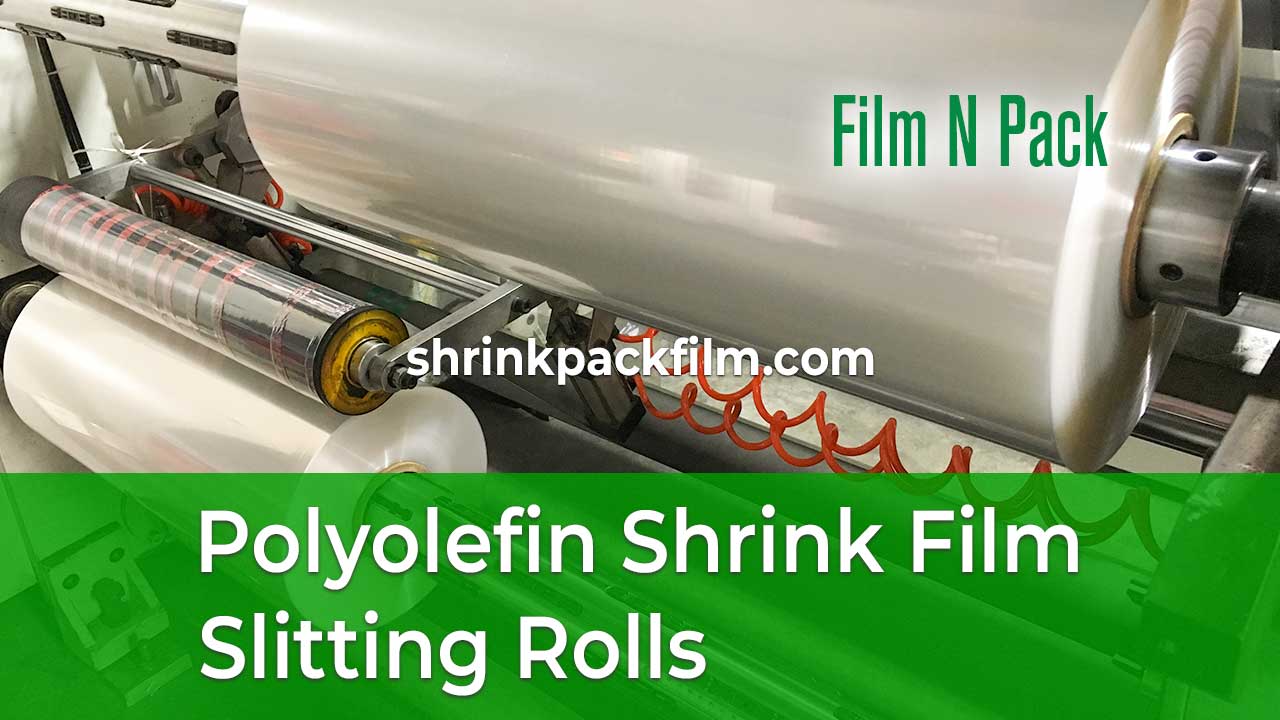

Step 5: Film Slitting ~ Production Process Polyolefin Packaging Material

Finally, the film is wound into rolls, ready for use. Throughout the manufacturing process, quality control measures are implemented to ensure consistent thickness, clarity, and strength of the film.

Polyolefin Shrink Film Manufacturer ~ International Supplier

We’re a leading manufacturer of polyolefin shrink films, offering high-quality packaging solutions for various industries. With years of experience in the industry, we have established itself as a reliable and trusted partner for businesses worldwide. Our polyolefin shrink films are known for their exceptional clarity, strength, and versatility, making them ideal for a wide range of applications. We prioritize customer satisfaction and strive to provide innovative and cost-effective packaging solutions tailored to meet the unique needs of our clients. With us, you can expect top-notch products, excellent service, and a commitment to sustainability.